Applicable scope: German standard, detailed specifications for the structural design of the bearing housing (made of cast iron or stamped steel plate), the position of bolt holes and the requirements for bearing capacity, applicable for equipment selection in the European market. GB/T 7810-2017

Name: “Rolling Bearings – Ball Bearings with Inner Raceway and Outer Raceball – External Dimensions”

Chinese National Standard:

Equivalent to ISO 113, stipulates the domesticized size parameters and tolerance standards for UCP bearings.

The surface roughness of the bearing seat is required to be ≤Ra 3.2 μm to ensure the accuracy of the installation plane.

II. Performance and Quality Certification Standards

Materials and Heat Treatment

Bearing steel standards:

The materials of the raceways and rolling elements should comply with ISO 683-17 (high-carbon chromium bearing steel), with hardness ≥ 58 HRC.

The cast iron material of the bearing housing should meet GB/T 9439 (gray cast iron parts), with tensile strength ≥ 250 MPa.

Salt spray test: According to ISO 9227 standard, the galvanized layer of the bearing housing should pass the 48-hour neutral salt spray test without rust.

Dynamic performance test

Life test: According to ISO 281 standard, the actual operating conditions (load, speed) are simulated to verify the theoretical life (L10).

Vibration and noise: Refer to ISO 15242, the vibration value of the bearing under no-load and rated speed should be ≤ 45 dB(A).

Industry certification

ISO 9001: Quality Management System Certification, ensuring production consistency.

IATF 16949: A specific standard for the automotive industry, applicable to automotive transmission system bearings.

FDA Certification: Food-grade lubricants (such as silicone-based lubricants) must comply with the standards of the U.S. Food and Drug Administration.

III. Special Industry Application Standards

Food Machinery

Compliant with the EHEDG/3-A hygiene design standard, the surface of the bearing housing needs to be resistant to corrosion from acid and alkali cleaning agents.

The grease needs to be NSF H1 certified (food-grade, pollution-free).

Agricultural machinery

According to ISO 5687 requirements, the bearing seal needs to be dust-proof (IP6X) and resistant to mud penetration.

Adaptability to extreme temperature differences (-30℃~120℃), refer to DIN 51821 low-temperature lubrication test.

Logistics conveying equipment

The shock resistance performance of the bearing housing needs to comply with ISO 13355 (vibration test for packaging machinery).

Low friction design, running torque ≤ 0.3 N·m (refer to ANSI/ABMA 9).

IV. Environmental Protection and Sustainable Development Requirements

RoHS/REACH: In the EU market, the content of harmful substances such as lead and cadmium needs to be restricted.

Low-carbon manufacturing: Refer to ISO 14064, reduce production energy consumption by 15% to 20%.

Selection and Compliance Suggestions

Export enterprises: Prioritize benchmarking against ISO/DIN standards to obtain CE or TUV certification.

Domestic projects: Follow GB/T 7810, and combine industry standards (such as JB/T 6640) to enhance adaptability to working conditions.

Latest Developments: Pay attention to the revision draft of ISO/TC4 (International Rolling Bearing Technical Committee), and promptly adjust processes.

For specific standard documents or certification guidance, you can contact the National Bearing Standardization Technical Committee (SAC/TC98).

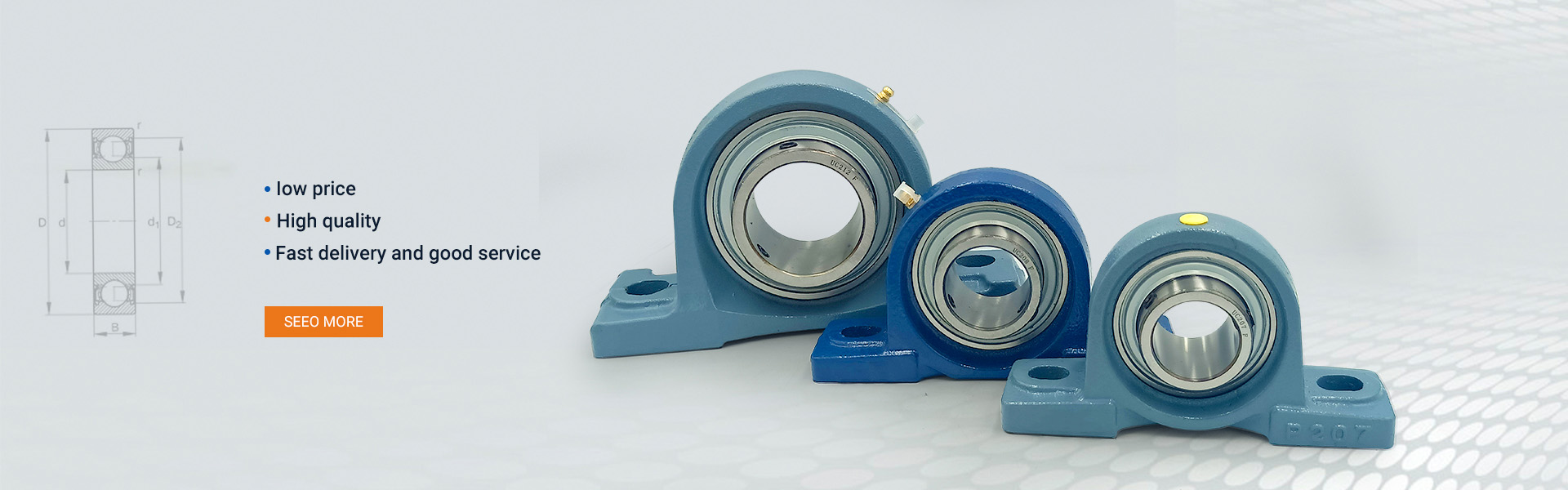

After years of efforts, VPN Pride Bearing has continuously improved its supply chain system based on the original factory for the double-seated spherical roller bearings, expanded the types of bearings it supplies, and has become a high-quality bearing supplier that integrates raw material procurement, production, inventory management and logistics. The quality of the bearings is designed and produced strictly in accordance with the IS0 international standards, and has passed the ISO9001:2015 quality management system certification.

Post time: Feb-17-2025