In today’s smart manufacturing sector, where the pursuit of ultimate efficiency and precision is relentless, a groundbreaking bearing technology is leading a new round of industry transformation. According to recent reports, a renowned international bearing manufacturer has successfully developed and launched a novel bearing solution specifically designed for high-precision robotic joints, which debuted at the Global Industrial Exposition this month, immediately capturing widespread industry attention.

This innovative bearing incorporates advanced materials science and manufacturing processes, combining nanoscale surface treatment technology with an intelligent lubrication system, significantly enhancing the bearing’s wear resistance, load capacity, and operational stability. Compared to traditional bearings, it extends service life by over three times under extreme conditions while reducing energy consumption by 20%, providing a solid foundation for high-precision motion control in smart manufacturing.

In practical applications, this bearing is widely used in automated production lines across sectors such as automobile manufacturing, electronic assembly, and medical device production, particularly in robotic joints requiring high precision, repeated positioning, and long-term continuous operation. A prominent German automaker, after adopting this new bearing, witnessed a 40% increase in robot operational efficiency on its production lines, a significant reduction in failure rates, shortened product delivery cycles, and substantially improved production efficiency and product quality.

Furthermore, the bearing integrates smart monitoring capabilities, enabling real-time monitoring of its operating status, including temperature, vibration, wear levels, and other critical parameters. Through IoT technology, this data is instantly fed back to the central control system, facilitating predictive maintenance and avoiding production line downtime due to bearing failures, further reducing maintenance costs and the risk of production disruptions.

“Amidst the backdrop of ‘Industry 4.0′ and ‘Made in China 2025,’ we are committed to driving the transformation and upgrading of the manufacturing industry through technological innovation,” stated the CEO of the bearing manufacturer at the launch event. “This new bearing is not only a testament to advancements in technology and materials science but also a precise grasp of future smart manufacturing trends. We believe it will bring unprecedented value to global industrial users.”

With the gradual promotion and application of this innovative bearing technology, it is expected to exert a profound impact on the global smart manufacturing industry in the coming years, ushering in a new era of manufacturing characterized by even greater efficiency, intelligence, and reliability.

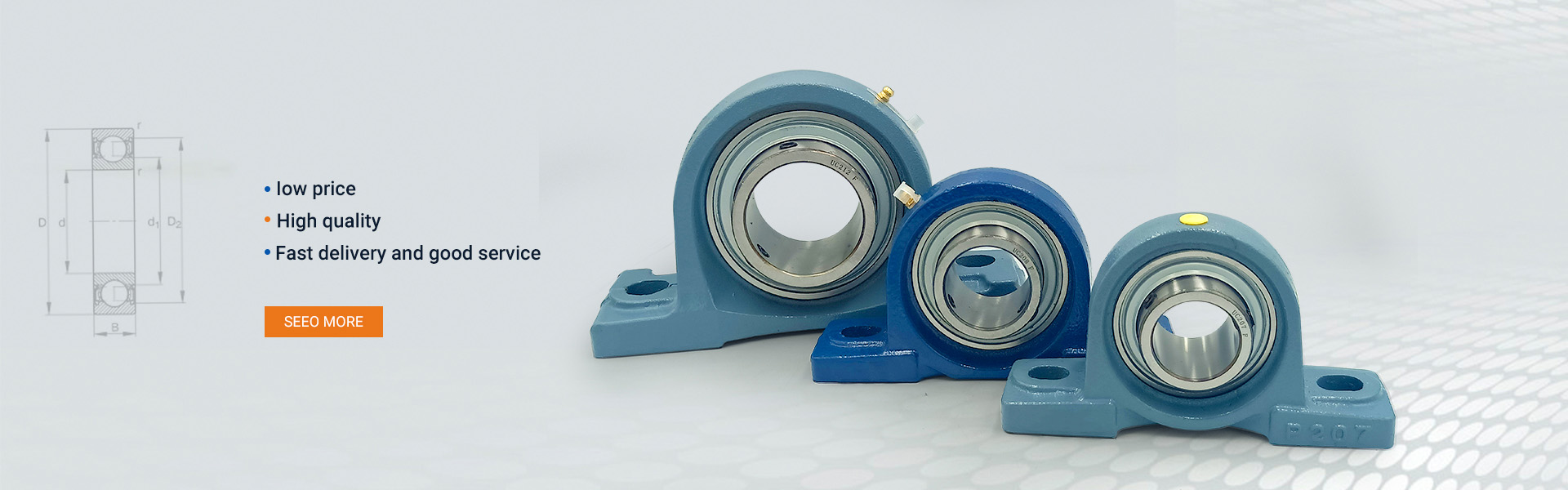

VPN Bearings has established close cooperative relationships with major domestic bearing brands in China. This cooperation model not only enriches the product line of VPN Bearings, enabling it to cover mainstream bearing categories in the market, but also provides customers with more choices. Through cooperation with domestic bearing brands, VPN Bearings can integrate resources from all parties to offer customers more competitive prices and comprehensive services.

While ensuring product quality, the VPN factory provides customers with competitive prices and comprehensive services. From bearing procurement to technical support and after-sales service, VPN Bearings can offer customers a one-stop solution, ensuring a convenient and efficient service experience throughout the entire procurement process.

In summary, with its professional team, robust supply chain system, and close cooperation with domestic bearing brands, VPN Bearings has successfully been exported to over 20 countries and regions, providing customers with a one-stop bearing procurement service. This comprehensive service model not only enhances the market competitiveness of VPN Bearings but also lays a solid foundation for its further development in the international market.

Post time: Feb-23-2025