Welcome to our websites!

-

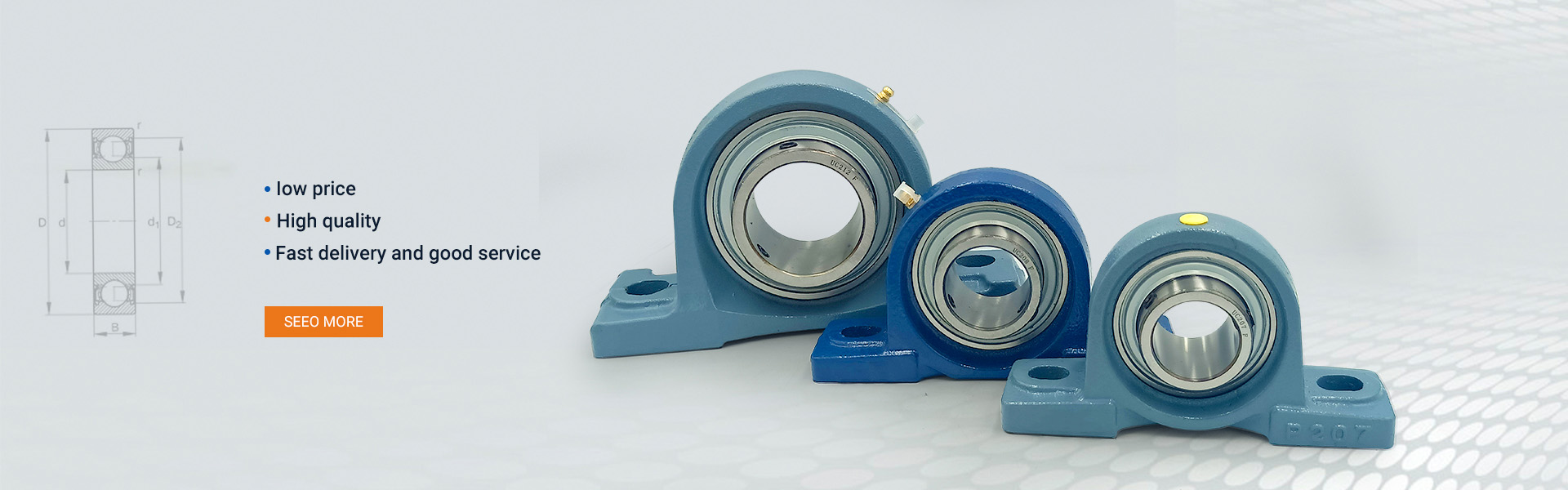

Pillow Block Bearing UCF200

The Pillow Block Bearing UCF200 is a spherical plain bearing unit with a housing. The core is the UC200 ball bearing (1-1/2-inch inner diameter), pre-assembled in a sturdy cast iron square housing. The base is equipped with four bolt holes for easy installation and fixation. It is designed to support rotating shafts, providing reliable support and is suitable for general industrial applications such as conveyors and agricultural machinery. -

1200

Split Bearing Housings are engineered for demanding industrial environments where ease of maintenance, durability, and reliability are critical. Their unique two-piece design enables rapid bearing inspection, replacement, and lubrication without disassembling connected machinery or disturbing shaft alignment. Below are their primary application scenarios -

1500

Split Bearing Housings are engineered for demanding industrial environments where ease of maintenance, durability, and reliability are critical. Their unique two-piece design enables rapid bearing inspection, replacement, and lubrication without disassembling connected machinery or disturbing shaft alignment. Below are their primary application scenarios -

THM500

Split Bearing Housings are engineered for demanding industrial environments where ease of maintenance, durability, and reliability are critical. Their unique two-piece design enables rapid bearing inspection, replacement, and lubrication without disassembling connected machinery or disturbing shaft alignment. Below are their primary application scenarios -

SAF600B

Split Bearing Housings are engineered for demanding industrial environments where ease of maintenance, durability, and reliability are critical. Their unique two-piece design enables rapid bearing inspection, replacement, and lubrication without disassembling connected machinery or disturbing shaft alignment. Below are their primary application scenarios -

SAF600A

Split Bearing Housings are engineered for demanding industrial environments where ease of maintenance, durability, and reliability are critical. Their unique two-piece design enables rapid bearing inspection, replacement, and lubrication without disassembling connected machinery or disturbing shaft alignment. Below are their primary application scenarios -

SAF500B

Split Bearing Housings are engineered for demanding industrial environments where ease of maintenance, durability, and reliability are critical. Their unique two-piece design enables rapid bearing inspection, replacement, and lubrication without disassembling connected machinery or disturbing shaft alignment. Below are their primary application scenarios -

SAF500A

Split Bearing Housings are engineered for demanding industrial environments where ease of maintenance, durability, and reliability are critical. Their unique two-piece design enables rapid bearing inspection, replacement, and lubrication without disassembling connected machinery or disturbing shaft alignment. Below are their primary application scenarios -

722500B

Split Bearing Housings are engineered for demanding industrial environments where ease of maintenance, durability, and reliability are critical. Their unique two-piece design enables rapid bearing inspection, replacement, and lubrication without disassembling connected machinery or disturbing shaft alignment. Below are their primary application scenarios -

722500A

Split Bearing Housings are engineered for demanding industrial environments where ease of maintenance, durability, and reliability are critical. Their unique two-piece design enables rapid bearing inspection, replacement, and lubrication without disassembling connected machinery or disturbing shaft alignment. Below are their primary application scenarios -

SD600

Split Bearing Housings are engineered for demanding industrial environments where ease of maintenance, durability, and reliability are critical. Their unique two-piece design enables rapid bearing inspection, replacement, and lubrication without disassembling connected machinery or disturbing shaft alignment. Below are their primary application scenarios -

SD500

Split Bearing Housings are engineered for demanding industrial environments where ease of maintenance, durability, and reliability are critical. Their unique two-piece design enables rapid bearing inspection, replacement, and lubrication without disassembling connected machinery or disturbing shaft alignment. Below are their primary application scenarios