Welcome to our websites!

-

SPHERICAL ROLLER BEARING-d 280-340mm

SPHERICAL ROLLER BEARING are divided into SPHERICAL ROLLER BEARING can be divided into symmetrical spherical roller bearings and asymmetric spherical roller bearings according to the shape of the roller section. The asymmetric SPHERICAL ROLLER BEARING are early products, mainly for the maintenance of the main engine. The symmetrical self-aligning roller bearings are rarely used in the new design of the main engine. Can withstand greater axial load, the running temperature of this bearing is low, so it can adapt to the requirements of higher speed, According to the inner ring with or without guard and the cage used, it can be divided into C type and CA type. The characteristics of C type bearing are that the inner ring has no guard and adopts steel plate stamping cage, while the characteristics of CA type Trayon bearing are that both sides of the inner ring have guard and adopts automobile solid cage. -

SPHERICAL ROLLER BEARING-d 120-150mm

SPHERICAL ROLLER BEARING has two rows of rollers, one shared spherical raceway in the outer ring and two raceways in the inner ring and is inclined to an Angle relative to the bearing axis. This clever structure makes it with automatic aligning performance, so it is not easy to be affected by the Angle of shaft and bearing box seat on the error or shaft bending, suitable for installation error or shaft deflection caused by Angle error occasions. In addition to bearing radial load, the bearing can also bear two-way axial load. -

SPHERICAL ROLLER BEARING-d 75-110mm

SPHERICAL ROLLER BEARING have good aligning performance. When the shaft is bent by force or installed with different cores, the bearings can still be used normally. The aligning property varies with the bearing size series, and the allowable aligning Angle is generally 1~2.5 degrees. -

SPHERICAL ROLLER BEARING-d 200-260mm

SPHERICAL ROLLER BEARING are divided into cylindrical inner holes and conical inner holes. The taper of the inner hole of the taper is 1:12 rear code K self-aligning roller bearing (type 153000 or type 113000) and 1:30 rear code K30 self-aligning roller bearing. When this kind of bearing is matched with a conical shaft, the radial clearance of the bearing can be adjusted by moving the inner ring along the axial direction. -

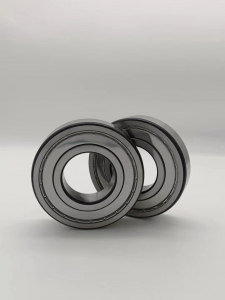

DEEP GROOVE BALL BEARING-6300 Series

Deep groove ball bearing has simple structure, and is easy to achieve higher manufacturing accuracy compared with other types, so it is convenient for serial mass production, manufacturing cost is also low, and it is widely used. In addition to the basic type of deep groove ball bearings, there are a variety of variant structures, such as: deep groove ball bearings with dust cover, deep groove ball bearings with rubber sealing ring, deep groove ball bearings with a stop groove, deep groove ball bearings with ball notched large load capacity, double row deep groove ball bearings -

STW stainless steel miniature linear series guide rail

The STW miniature guide is stainless steel. StainlessSteel (stainless steel) is short for stainless acid-resistant steel, resistant to air, steam, water and other weak corrosion medium or steel with stainless properties called stainless steel -

ST stainless steel miniature linear series guide rail

The ST miniature guide is stainless steel. StainlessSteel (stainless steel) is short for stainless acid-resistant steel, resistant to air, steam, water and other weak corrosion medium or steel with stainless properties called stainless steel -

MGN-C/MGN-H-MGN miniature linear series guide rail

The function of linear guide is to support and guide the moving parts, reciprocating linear motion according to the given direction. According to the friction properties, linear motion guide can be divided into sliding friction guide, rolling friction guide, elastic friction guide, fluid friction guide and so on. -

MGN miniature linear series guide rail-MGN-C/MGN-H

The function of linear guide is to support and guide the moving parts, reciprocating linear motion according to the given direction. According to the friction properties, linear motion guide can be divided into sliding friction guide, rolling friction guide, elastic friction guide, fluid friction guide and so on. -

HG series linear guide rail-HGW-CC/HGW-HC

The function of linear guide is to support and guide the moving parts, reciprocating linear motion according to the given direction. According to the friction properties, linear motion guide can be divided into sliding friction guide, rolling friction guide, elastic friction guide, fluid friction guide and so on. -

HG series linear guide rail-HGL-CA/HGL-HA

Linear guide is a precision part, so it is required to have a very careful attitude when using, even if the use of high performance linear guide, if the use of improper, can not achieve the expected performance effect, and easy to damage the linear guide. Therefore, the following precautions should be paid attention to when using linear guides: prevent rust, keep the environment clean, install carefully, and install tools properly -

HG series linear guide rail-HGH-CA/HGH-HA

linear guide is to support and guide the moving parts, reciprocating linear motion according to the given direction. According to the friction properties, linear motion guide can be divided into sliding friction guide, rolling friction guide, elastic friction guide, fluid friction guide and so on.